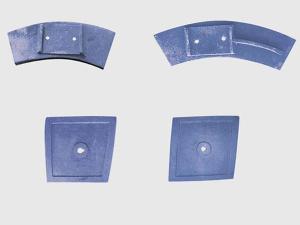

Concrete Mixer Liner Plates

Name: Liner Plate, Wear Liner

Materials: High manganese steel, modified high manganese steel, alloy steel, bimetal composite material, high chromium material, ultra high chromium cast iron, multi-component alloy steel

Application: The concrete mixer parts are mainly used to protect the mixer drums.

Customizable or not: Customizable; tailor made to customers' drawings or samples

Part model: Based on customer's needs

Order quantity: Based on customer's needs

Service life: Enough time for mixing about 200,000 CBM concrete

Liner Plate Applications

Casting parts is a prominent mixing plant parts supplier, You'll find top quality OEM wear parts designed specifically for various brands of concrete mixers by our engineers. For example, we are proud to make liner plates to your specifications to replace the authentic parts of SANY, ZOOMLION, NFLG, SICOMA, ELBA, XCMG, NIKKO, Teka, JS, and other concrete mixers. They are perfect for cement, chemical, power, metallurgy and other industries.

Liner Plate Moulds

Liner Plate Moulds-

Side liner plates for SICOMA concrete mixer

-

Liners plates for SICOMA concrete mixer

- Liner plates for the JS1500M concrete mixer of SANY90 concrete batch plant

-

ZOOMLION JS3000 concrete mixer liner plates

-

JS3000 concrete mixer liner plates for HZS180 commercial concrete batch plant

- Mixing blades, liner plates and mixing arms for ELBA120 concrete mixer; ELBA60 concrete mixer parts

- Liner plates for NIKKO DSF167, DSF225, DSF275 and DSF330 concrete mixer

- Liner plates for NIKKO DSF167, DSF225, DSF275 and DSF330 concrete mixer

-

NFLG concrete mixer mixing blades and liner plates

- SICOMA HZS120 concrete mixer side liners

- SICOMA HZS120 concrete mixer side liner

| Hardness | 52-62HRC |

| Life | more than 200000 cubic meter concrete or 300000 tons asphalt |

| Standards | CN:KM TB Cr 15-25-GTUS:ASTM A532 Class Two Type D |

| Extension strength | 380 N/mm2 |

| Elongation at break | 1% |

| Shock impact (resistance) value | >5 ak N.M/CM2 |

| Flexural strength | >600 ak N.M/CM2 |

| Certifications | ISO9001:2008,ce |

| Metallographic organization | M+M7C3+M23C6 |

| Process | Lost Foam Casting |

| Name | Chemical Compositions % | Hardness | ||||||||

| C | P | S | Si | Mn | Cr | Ni | Mo | Cu | ||

| Special high chrome steel | 2.8~3.1 | <0.06 | <0.06 | 0.8 | 0.8 | 22 | <1 | <1 | <0.5 | 62 |

| High chrome steel | 2.8~3.1 | <0.06 | <0.06 | 0.8 | 0.8 | 15 | <0.5 | 52 | ||

| Low chrome steel | 2.8~3.1 | <0.06 | <0.06 | 0.8 | 0.8 | 3 | 48 | |||

| High manganese steel | 1.2 | <0.06 | <0.06 | 16 | 45 | |||||

| Alloy steel casting | 1.2 | <0.06 | <0.06 | 2 | 1 | 45 | ||||