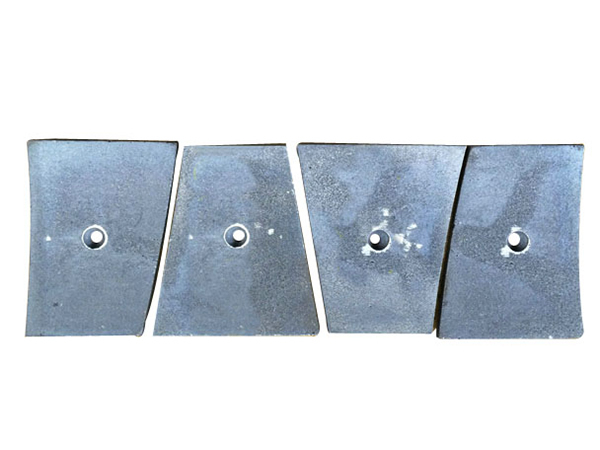

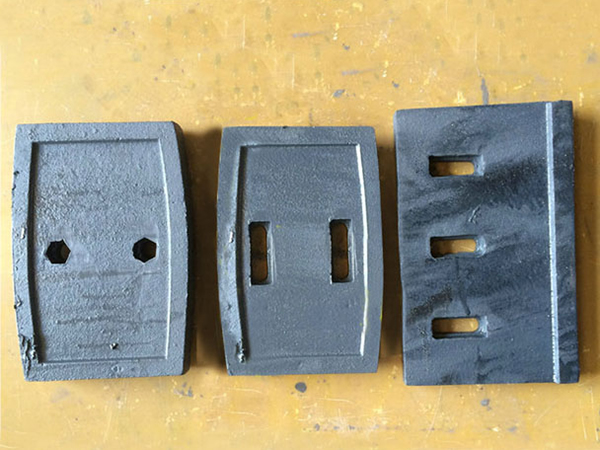

Concrete Mixer Mixing Blades

Name: Mixing blade

Suitable for: Concrete batch plant, concrete mixers of various brands including SANY, ZOOMLION, NFLG, SICOMA, XCMG, Teka, Fangyuan, BHS, Huajian, Shaoguan, JS, etc.

Materials: High manganese steel, modified high manganese steel, alloy steel, bimetal composite material, high chromium material, ultra high chromium cast iron, multi-component alloy steel

Customizable or not: Yes

Part model: Based on customer's needs

Order quantity: Based on customer's needs

Applications

The concrete mixer replacement parts are ideal for the concrete mixers used in cement, chemical, power, metallurgy and other industries.

- Concrete mixer blades for SICOMA mixer

- Concrete mixer blades for SICOMA mixer

- Mixing blades for SANY JS3000 concrete mixer

- Mixing blades for HUAJIAN JS1500b, JS2000b and JS3000b concrete mixers

-

Mixing blades for ZOOMLION JS3000 mixer

- JS3000 concrete mixer mixing blades for NFLG HZS180 concrete batch plant

- Mixing blades for BHS2.0, BHS3.0, BHS4.5 and DKXS concrete mixers

- Mixing blades for ELBA1650 and ELBA60 concrete mixers

- Mixing blades for Nikko DSF167, DSF225, DSF275 and DSF330 concrete mixers

- Mixing blades for SHAOGUAN JS3000FG and JS2000FA concrete mixers

Order Information

1. Concrete Mixer Spare Parts

a. Quality standard: National Standard GB/T8263-1999 (Substitute Japanese and ASME products)

b. Supporting concrete mixers: SICOMA, BHS, YKYC, TEKA, SANY, NFLG, FYG, DG; AMMANN, NIKKO, ACP, MARINI; ABG, VOEGELE, DEMAG, DYNAPAC, XCMG

c. Metallographic organization: M+M7C3+M23C6

d. Shock toughness: 6-8 J/cm2

| Hardness | 52-62HRC |

| Life | More than 200,000 cubic meter concrete or 300,000 tons asphalt |

| Standards | CN:KM TB Cr 15-25-GTUS:ASTM A532 Class Two Type D |

| Extension strength | 380 N/mm2 |

| Elongation at break | 1% |

| Shock impact (resistance) value | >5 ak N.M/CM2 |

| Flexural strength | >600 ak N.M/CM2 |

| Certifications | ISO9001:2008, |

| Metallographic organization | M+M7C3+M23C6 |

| Process | Lost Foam Casting |

| Name | Chemical Compositions % | Hardness | ||||||||

| C | P | S | Si | Mn | Cr | Ni | Mo | Cu | ||

| Special high chrome steel | 2.8~3.1 | <0.06 | <0.06 | 0.8 | 0.8 | 22 | <1 | <1 | <0.5 | 62 |

| High chrome steel | 2.8~3.1 | <0.06 | <0.06 | 0.8 | 0.8 | 15 | <0.5 | 52 | ||

| Low chrome steel | 2.8~3.1 | <0.06 | <0.06 | 0.8 | 0.8 | 3 | 48 | |||

| High manganese steel | 1.2 | <0.06 | <0.06 | 16 | 45 | |||||

| Alloy steel casting | 1.2 | <0.06 | <0.06 | 2 | 1 | 45 | ||||