As a recognized wear part solution provider, Casting parts has offered global customers a vast variety of replacement wear parts made to customers' specifications. Typical customers are shown below:

1. Customer from Colombo, Sri-Lanka

Customer type: Quarry & Aggregate Supplier

Delivery Cycle: 25 days

Products: Jaw Plates & Cone crusher liners for Korean Crushers

Cooperation Process: Casting parts Casting has a lot of operation and experience in Sri-Lanka depending on our understanding of different stones & quarry. We have offered various solutions with our wear parts for different quarries. And after sample testing, we have won a long term business with local one of the biggest quarry and aggregates suppliers in Colombo.

2. Customer from Jeddah, Saudi Arabia

Customer type: Mining Contractor

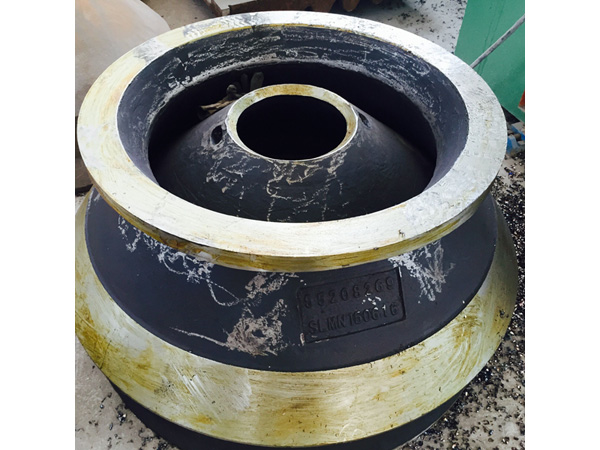

Products: Symons 4.25 and 5.5 concave and mantle

Delivery Cycle: 35 days

Cooperation process: In 2013, we attended the Saudi PMV Show held in Saudi Arabia and attracted the attention of this local big mining contractor. Soon, we established a cooperative relationship for the Symons cone crusher liners which won their satisfaction on our parts’ quality and service life. Now 5-8 20GP containers of Symons cone crusher parts will be ordered by this customer per year and delivery cycle is about 35days.

3. Customer from SRI-LANKA

Customer type: Road Development Authority/Contractors

Products: Blow Bars & Jaw crusher parts for SHANBAO Crusher Plant; mixing arms and filter bags for Asphalt Plant

Delivery Cycle: 30days

Cooperation process: Based on our reputation and connections in the region, we won the opportunity to cooperate with the Ministry of Road Development Authority of Sri-Lanka and supply all the wear parts for their 8 Shanbao Crusher plants and 15 Asphalt Mixing Plants, including mixing blades, arms, liners and dust filter bags.

4. Customer from Kula Lumpur, Malaysia.

Customer type: Concrete & Asphalt Plant Manufacturer

Products: Mixing Arm, Blade and Liners for Sicoma Asphalt Mixers

Delivery Cycle: 21 days

Cooperation process: In the long history of Casting parts in mixing plant parts industry, we have supplied many wear parts for Sicoma, BHS, JS and other brand pan and twin shaft mixers to plant manufacturers and end users. We also supply the wear parts and filter bags for Ammann, Marini, Lintech, Nikko, Speco, XRMC, DG, NFLG , CA-LONG, TTM, Astech and Roady asphalt plants.

5. Customer from Sochi, Russia

Customer type: Mining Machinery & Spare Parts Dealer

Products: Cone Crusher Liners / Svedala, Sandvik and Metso

Delivery Cycle: 35 days

Cooperation process: In April, 2015, we attended an exhibition of Mining held in Moscow, Russia. Very soon we made the deal with a local dealer of the wear parts for mining industry, especially for European and American brand crushers such as Svedala, Sandvik, Metso, TRIO, etc. Based on the satisfaction on our casting quality and perfect surface finishing, we are repeating the orders as the major supplier for this vendor.

6. Sri-Lankan Customer

Customer type: Wear Parts Buyer

Products: Crusher spare parts

Delivery cycle: 30 days

Cooperation Process: The customer contacted us in 2011 using the information we put on our website. We mainly supplied the customer with wear parts for SHANBAO crushers. Now, they can purchase up to an average 2 20GP containers of parts per month.

7. Russian Customer

Customer type: Wear Parts Buyer

Products: Asphalt Plant Spare Parts

Delivery cycle: 40 days

Cooperation Process: In the early of 2014, we appointed representatives to investigate the local market of Russia and established cooperation relationship with the customer that time. Although our cooperation did not last for a long time, the customer purchased a huge amount of parts from us. As such, we built a marketing department for customers in Russia.

8. Malaysian Customer

Customer type: Wear Parts Buyer

Products: Asphalt Plant Spare Parts

Delivery cycle: 25 days

Cooperation Process: Our cooperation started from the Burma Shanghai 2008. We mainly supplied this customer with asphalt mixer parts and filter bags. They not only purchased our products, but also required us to offer technical supports. Each year, we appointed engineers to their work site to offer free repair and maintenance service.