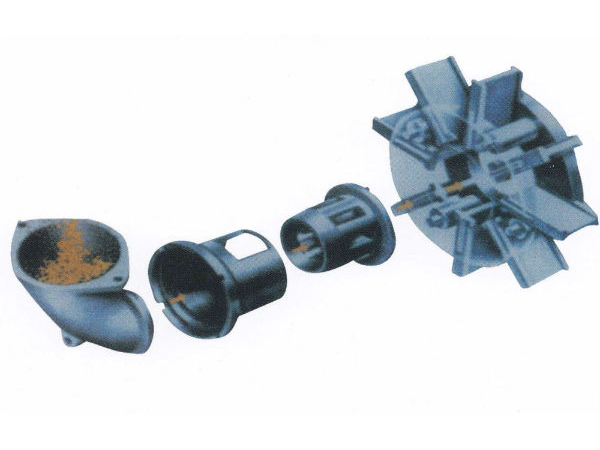

Blast Wheel Blades / Vanes

Blast Wheel Structure

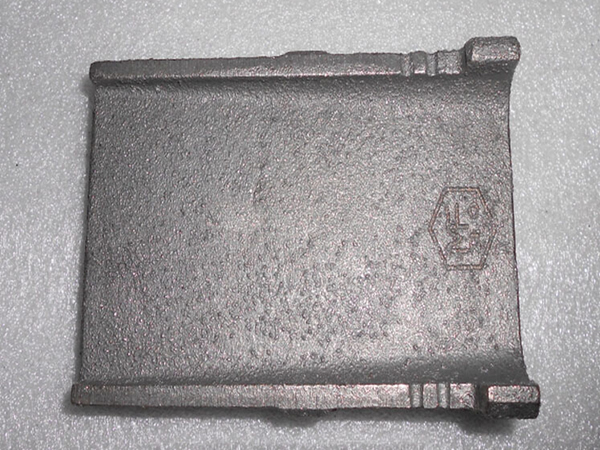

Name: Blast Wheel Blades, Blast Wheel Vanes

Materials: High chromium alloy cast iron, high manganese alloy steel

Applicable machine: Shot blasting machine

Customizable or not: Yes

Part model: Based on customers needs

Order quantity: Based on customers needs

Applicable media: Steel grit or shot

Principle

A total of 8 blast wheel blades are mounted on the wheel assembly. An impeller that rotates synchronously with the critical shot blast parts carries the shot to an opening in the control cage, from where it is discharged on to the bladed wheel. There, the shot is shoveled by the wheel blades and is further accelerated as it is threw onto the work.

Impeller keeps synchronous rotation with the blast wheel blades, making sure that shot can be moved to the blades without vibration, thus reducing abrasion of the important shot blasting supplies.

We can customize replacement blast wheel blades for the shot blasting machines of following brands: SINTO, DISA, PANBORN, WHEELABRATOR and OMSG

| High chromium alloy cast iron | High manganese alloy steel | |||||||

| Chemical compositions % | C | 2.7-3.1 | Mechanical properties | Tensile strength kg/mm2 | ≤ 40 | Chemical compositions % | C | 0.9-1.3 |

| Si | <1.0 | Si | ≤0.8 | |||||

| Mn | 0.8-1.1 | Hardness HS | > 70 | Mn | 11-14 | |||

| P | <0.06 | P | <0.07 | |||||

| Cr | 25-30 | Impact resistance kgm/cm 2 | > 0.3 | S | <0.05 | |||

| S | <0.05 | 0 | 0 | |||||

- Blast wheel blade for DISA shot blasting machine

- Blast wheel blade for DISA shot blasting machine

- Blast wheel blade for Taiwan Chunhui shot blasting machine

- Blast wheel blade for SINTO shot blasting machine

As professional shot blasting machine parts manufacturer, we are able to supply other replacement parts: