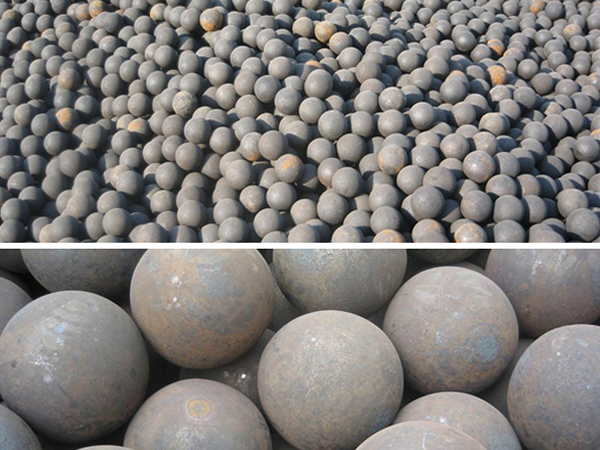

Grinding Balls

Common names: Grinding balls, high chromium steel balls, low chromium steel balls, wear resistant steel balls

Applicable equipment: Ball mills

Main materials: High and low chromium castings, high and low chromium alloy

Materials to be ground: common ores and gangue

Introduction

Grinding balls are grinding media used in ball mills to crush or grind materials such as cement, minerals, etc. The ball mill spares are widely applied in cement plants, power plants, etc. Some balls made of special materials have been extensively used in all kinds of fields such as high chromium steel balls, low chromium steel balls, multi-component alloy steel balls, and more.

Categories and Specifications

1. Low chromium grinding balls: 20-130mm

2. Medium chromium grinding balls: 20-130mm

3. High chromium grinding balls: 20-130mm

Grinding Ball Sorting Principle

1. As the materials to be ground have high hardness, balls of large diameters should be selected.

2. The larger diameter the ball mill has, the higher impact it will produce. Then the steel balls of small diameters should be selected.

3. When a ball mill employs double-layer intermediate diaphragm, the grinding balls in it are smaller than those in the ball mill that has the same discharge section and uses single layer intermediate diaphragm.

4. Generally, the chrome steel balls with large and small sizes are fewer than those with medium size.

a. For ball mills in different models, the ball load is also different. For example, the maximum ball load of MQG1500×3000 ball mill is varies from 9.5 tons to 10 tons according to its capacity of 100-150tons.

b. In the first feeding of grinding balls, large balls (120-100mm) occupies 30%-40% load, medium sized balls (80mm) 40%-30% and small balls (60-40mm) 30%.

c. During the running-in process, the ball load is just 80%. Left 20% can be added into the chamber after the ball mill runs well.

Manufacturing Process

1. High quality steel scraps, chromium alloy and other alloy materials are first melted in medium frequency furnace. After microalloying and tempering treatments, the steel balls are molded via casting process.

2. Casting under constant temperature ensures the finished steel castings are free from the quality defects such as sand inclusion, air pore, etc.

3. Tempering process can change the inner structure of grinding balls, reduce inner stress, ensure crushing rate and further improve properties of the ball mill parts.

4. State of the art spectrum tests are applied before and after melting processes, and for semi finished and finished products to ensure stable chemical compositions and properties.

| Name | Chemical Composition ( % ) | |||||||

| C | Si | Mn | Cr | Mo | Cu | P | S | |

| Medium chromium grinding ball | 2.2-3.3 | ≤1.2 | 0.5-1 | 3-6 | 0.6-1 | ≤1 | ≤0.05 | ≤0.05 |

Mechanical Properties and Metallographic Structure

| Name | Surface hardness (HRC) | Impact value (J/cm2) | Metallographic structure | Falling ball impact and fatigue life | |

| Medium chromium grinding ball | ≥48 | ≥3 | P+C | ≤Φ80 | ≥15000h |

| ≥Φ80 | ≥10000h | ||||

| P-pearlite ; C- carbide | |||||

| Diameters ( mm ) | Piece Weight ( kg ) | Quantity ( pcs/t ) |

| Φ30 | 0.11 | 9091 |

| Φ40 | 0.25 | 3891 |

| Φ50 | 0.50 | 2000 |

| Φ60 | 0.86 | 1153 |

| Φ70 | 1.37 | 729 |

| Φ80 | 2.05 | 487 |

| Φ90 | 2.90 | 345 |

| Φ100 | 4.00 | 250 |

| Φ110 | 5.30 | 188 |

| Φ120 | 6.80 | 147 |

| Φ130 | 7.70 | 129 |

| Φ140 | 8.74 | 114 |