Our lost foam production line, automatic dust-free production line, and DISA vertical extrusion molding line imported from Denmark, are all utilized by our mold production and casting process. Apart from the production line, we have a pouring furnace, molding machine, foaming machine, mold drying room, automatic molding machine, dust-cleaning equipment, automatic annealing furnace, a number of other high quality processing equipment in order to ensure efficient mass production.

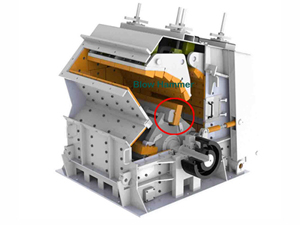

Automatic molding machine

This automatic molding machine minimizes the amount of manual labor performed by our operators.

Lost foam production line

Lost foam castings have finer grain and dense structures, also, higher dimensional accuracy.

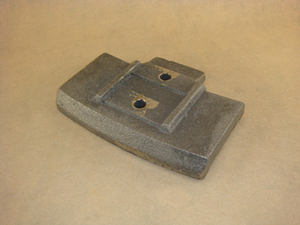

Casting technology

We adopt EPC casting or vacuum casting technology and we have the production capacity of 5000 ton castings.

DISA vertical extrusion moulding line

We are much more efficient in the production of wear resistant parts because we are equipped with a DISA vertical extrusion molding line imported from Denmark and we have skillful technicians to operate it.