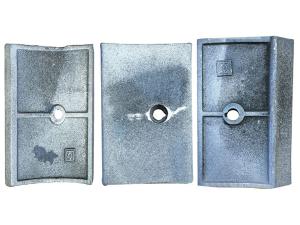

Asphalt Mixer Liner Plates

Name: Liner Plate

Suitable For: Asphalt plant, asphalt mixers of various brands

Materials: Ni-hard or high chromium cast iron, high manganese steel, modified high manganese steel, alloy steel, bimetal composite material, high chromium material, ultra high chromium cast iron, multi-component alloy steel

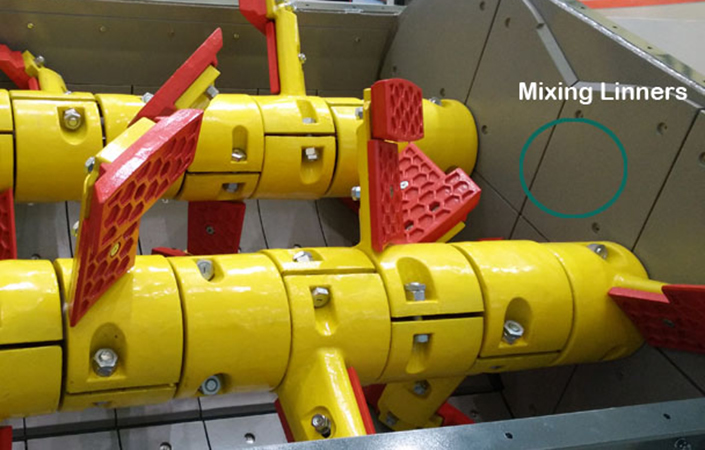

Applications: The twinshaft mixer wear plates are perfect replacement parts for various brands of asphalt plants in cement, chemical, power, metallurgy and other industries. They are used to protect the mixer drums.

Customizable or not: Yes

Technology: Mould casting

Usage time: About 200,000 CBM cements or asphalt

Part model: Based on customer's needs

Order quantity: Based on customer's needs

Packaging details: Composite material box

Delivery cycle: 35 days

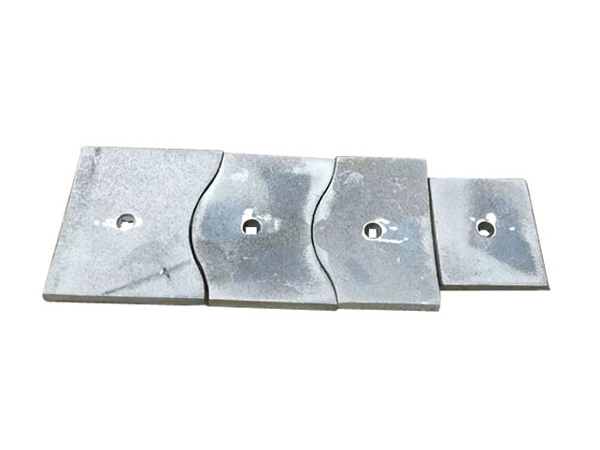

Asphalt Mixer Liner Plate Structure

Liner plates are indispensable wear parts of asphalt or concrete mixers, designed to protect the mixer drums. As a professional mixer wear parts manufacturer, we take pride in manufacturing mixer drum liners for various brands of mixing plants to customers' specifications, Including AMMANN, MARINI, SPECO, PARKER, LINTECH, LINHOFF, ASTEC, BENNIGHOVEN, SANY, ZOOMLION, NFLG, CA-LONG, TTM, XCMG, HUATONG, DG, ROADY, XRMC, XUETAO, XITONG, and more.

-

Liner plates for SPECO LB1000 asphalt mixer

- Liner plates for SPECO TSAP-2000, TSAP-3000 and TSAP-4000 asphalt mixers

- Liner plates for SPECO TSAP-800, TSAP-1000 and TSAP-1300 asphalt mixers

- Liner plates for SANY LB2000E, LB3000, LB4000 and 320 asphalt plants

- Mixer liner for XCMG LQC320A TSAP-1000 and TSAP-1300 asphalt plant

- Liner plates for AMMANN LB and AMMANN3000 asphalt plants

- Liner plates for the mixer in SIM3000 asphalt plant

- Mixer liner plates for nikko160, 240, 320 and NBD320 asphalt plants

- Mixer liner plates for nikko160, 240, 320 and NBD320 asphalt plants

-

Mixer liner plates for LINTEC320 asphalt plant

- Mixing blade for MARINI320 asphalt mixer; Liner plate for MARINI3000 asphalt mixer

-

Liner plate for BENNIGHOVEN asphalt mixer

Mixing blade for AMMANN LB4000 asphalt

Mixing blade for AMMANN LB4000 asphalt Liner Plate Moulds

Liner Plate Moulds | Hardness | 52-62HRC |

| Life | more than 200000 cubic meter concrete or 300000 tons asphalt |

| Materials | high chromium cast iron/steel |

| Standards | CN:KM TB Cr 15-25-GTUS:ASTM A532 Class Two Type D |

| Extension strength | 380 N/mm2 |

| Elongation at break | 1% |

| Shock impact (resistance) value | >5 ak N.M/CM2 |

| Flexural strength | >600 ak N.M/CM2 |

| Certifications | ISO9001:2008,ce |

| Metallographic organization | M+M7C3+M23C6 |

| Process | Lost Foam Casting |

Chemical Compositions

| Name | Chemical Compositions % | Hardness | ||||||||

| C | P | S | Si | Mn | Cr | Ni | Mo | Cu | ||

| Special high chrome steel | 2.8~3.1 | <0.06 | <0.06 | 0.8 | 0.8 | 22 | <1 | <1 | <0.5 | 62 |

| High chrome steel | 2.8~3.1 | <0.06 | <0.06 | 0.8 | 0.8 | 15 | <0.5 | 52 | ||

| Low chrome steel | 2.8~3.1 | <0.06 | <0.06 | 0.8 | 0.8 | 3 | 48 | |||

| High manganese steel | 1.2 | <0.06 | <0.06 | 16 | 45 | |||||

| Alloy steel casting | 1.2 | <0.06 | <0.06 | 2 | 1 | 45 | ||||