Cast Steel Shot

Name: Cast Steel Shot

Materials: The steel shot is cast from high quality steel scraps

Applicable machine: Superior blasting abrasives or steel abrasives applied to all kinds of shot blasting machines, blast wheels, sandblasting equipment, steel pretreatment line, etc.

Customizable or not: Yes

Part model: Based on customers needs

Order quantity: Based on customers needs

Samples for Russian customers

Cast Steel Shot Applications

Casting parts cast steel shots are perfect for blasting, rust removing, sand blasting, surface strengthening, surface preparation, and other applications.

1. Shot blasting: On die castings, forgings, steel plates, rolled steels, H steels and steel profiles

2. Rust removing: For die castings, forgings, steel plates, rolled steels, H steels and steel profiles

3. Surface strengthening: For heat treated workpieces, gears

4. Sand blasting

5. Pre-treatment: Coating pre treatment, surface pretreatment, ship plate pretreatment, steel profiles pretreatment, rolled steels pretreatment, steel plates pretreatment

| Name | Cast steel shot | |

| Chemical compositions | C | 0.70 ~ 1.20% |

| Mn | 0.35 ~ 1.20% | |

| Si | 0.40 ~ 1.20% | |

| S | ≤0.05% | |

| P | ≤0.05% | |

| Average hardness ( Tested under 500g load ) |

Common: 40 ~ 50HRC (377 ~ 509HV) Special: 52 ~ 56HRC (543 ~ 620HV) Special: 56 ~ 60HRC (620 ~ 713HV) |

|

| Hardness deviation | ±3.0HRC or ±40HV | |

| Metallographic structure | Even tempered martensite or tempered troostite + diffused carbide | |

| Minimum density ( Tested using ethyl alcohol substitution method) |

7.2g /cm3 | |

| Mesh | mm | Cast Steel Shot | ||||||||||

| 2.5 | 2.0 | 1.7 | 1.4 | 1.2 | 1.0 | 0.8 | 0.6 | 0.5 | 0.3 | 0.2 | ||

| 7 | 2.80 | all pass | ||||||||||

| 8 | 2.36 | all pass | ||||||||||

| 10 | 2.00 | 85%min | all pass | all pass | ||||||||

| 12 | 1.70 | 97%min | 85%min | 5%max | all pass | |||||||

| 14 | 1.40 | 97%min | 85%min | 5%max | all pass | |||||||

| 16 | 1.18 | 97%min | 85%min | 5%max | all pass | |||||||

| 18 | 1.00 | 96%min | 85%min | 5%max | all pass | |||||||

| 20 | 0.850 | 96%min | 85%min | 10%max | all pass | |||||||

| 25 | 0.710 | 96%min | 85%min | 10%max | ||||||||

| 30 | 0.600 | 96%min | 85%min | all pass | ||||||||

| 35 | 0.500 | 97%min | 85%min | 10%max | ||||||||

| 40 | 0.425 | 97%min | all pass | |||||||||

| 45 | 0.355 | 80%min | 10%max | |||||||||

| 50 | 0.300 | 90%min | ||||||||||

| 80 | 0.180 | 80%min | ||||||||||

| 120 | 0.125 | 90%min | ||||||||||

| 200 | 0.075 | |||||||||||

| 325 | 0.045 | |||||||||||

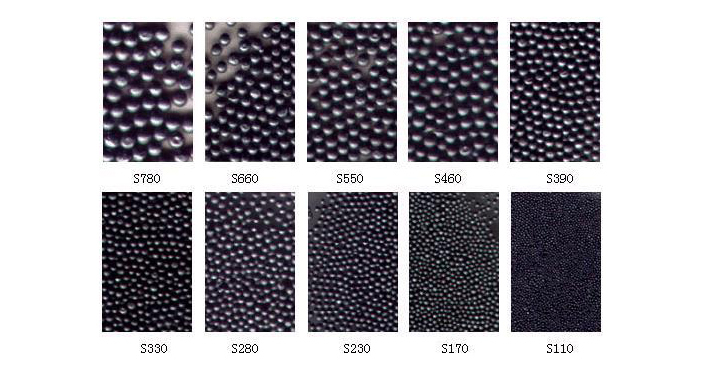

| SAE | S-780 | S-660 | S-550 | S-460 | S-390 | S-330 | S-280 | S-230 | S-170 | S-110 | S-70 | |

Cast Steel Shot Classification Chart